Bin picking

Bin picking automates the picking of randomly placed parts from bins or containers, even when they are at different heights, angles and positions.

As an official distributor of Mech-Mind, HUPICO supplies industrial 3D cameras and AI software that enable robots to perform complex gripping tasks quickly, accurately and reliably. The solutions combine advanced 3D imaging, smart object recognition and automated robot control, making processes not only more efficient but also more consistent.

Advantages of Mech-Mind's 3D vision solutions

-

High accuracy: Detects even small or reflective parts with precision down to 0.03 mm (depending on the camera module).

-

Quick changeover: Easy reconfiguration for new product types thanks to the flexible software environment.

-

Robust design: IP65/IP67 rated, so resistant to dust, water and shocks.

-

Short cycle times: Fast image capture (0.3 seconds) and efficient gripping paths for maximum productivity.

-

Wide range of applications: Suitable for sectors such as automotive, metalworking, logistics, electronics and food.

Suitable for all major robot brands

Mech-Mind's 3D cameras integrate seamlessly with

- EPSON

- ABB

- KUKA

- FANUC

- ...and many others.

Because the systems are brand-independent, you can always choose the robot that best suits your application – from compact cobots to powerful industrial robots.

Typical applications

Whether simple or complex products, Mech-Mind bin picking can handle a wide range of objects:

- Bulk metal parts

- Complex shaped castings or painted surfaces

- Small precision parts (screws, bolts, connectors)

- Irregular products, bags and boxes

LSR XL-GL

- Working distance: 1600–3500 mm

- Near FOV: 1280 × 1280 mm @ 1.6 m

- Far FOV: 3000 × 2800 mm @ 3.5 m

- Resolution: Depth map 2448 × 2040

- RGB: 4000 × 3000 / 2000 × 1500

- Megapixels: –

- Repeatability (Z σ): 0.2 mm @ 3.0 m

- VDI/VDE accuracy: 1.0 mm @ 3.0 m

- Exposure time: 0.6 – 1.1 s

- Baseline: 800 mm

- Dimensions: 942 × 88 × 116 mm

- Weight: 4.5 kg

LSR XL-GL

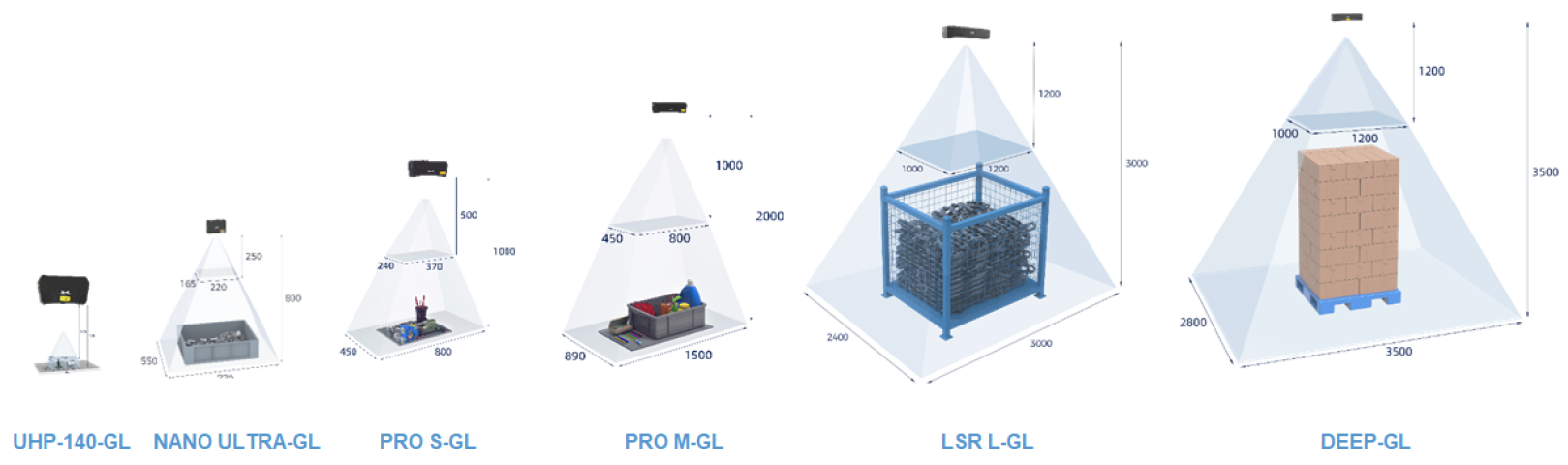

LSR L-GL

- Working distance: 1200–3000 mm

- Near FOV: 1200 × 1000 mm @ 1.2 m

- Far FOV: 3000 × 2400 mm @ 3.0 m

- Resolution: Depth map 2048 × 1536

- RGB: 4000 × 3000 / 2000 × 1500

- Megapixels: –

- Repeatability (Z σ): 0.5 mm @ 3.0 m

- VDI/VDE accuracy: 1.0 mm @ 3.0 m

- Exposure time: 0.5 – 0.9 s

- Baseline: 380 mm

- Dimensions: 459 × 77 × 86 mm

- Weight: 2.9 kg

LSR L-GL

LSR S-GL

- Working distance: 500–1500 mm

- Near FOV: 480 × 360 mm @ 0.5 m

- Far FOV: 1500 × 1200 mm @ 1.5 m

- Resolution: Depth map 2048 × 1536

- RGB: 4000 × 3000 / 2000 × 1500

- Megapixels: –

- Repeatability (Z σ): 0.2 mm @ 1.5 m

- VDI/VDE accuracy: 1.0 mm @ 1.5 m

- Exposure time: 0.5 – 0.9 s

- Baseline: 140 mm

- Dimensions: 228 × 77 × 126 mm

- Weight: 1.9 kg

LSR S-GL

PRO M-GL

- Working distance: 1000–2000 mm

- Near FOV: 800 × 450 mm @ 1.0 m

- Far FOV: 1500 × 890 mm @ 2.0 m

- Resolution: 1920 × 1200 (Depth map)

- RGB: 4000 × 3000 / 2000 × 1500

- Megapixels: 2.3 MP

- Repeatability (Z σ): 0.2 mm @ 2.0 m

- VDI/VDE accuracy: 0.2 mm @ 2.0 m

- Exposure time: 0.3 – 0.6 s

- Baseline: 270 mm

- Dimensions: 353 × 57 × 100 mm

- Weight: 1.9 kg

PRO M-GL

PRO S-GL

- Working distance: 500–1000 mm

- Near FOV: 370 × 240 mm @ 0.5 m

- Far FOV: 800 × 450 mm @ 1.0 m

- Resolution: 1920 × 1200 (Depth map)

- RGB: 4000 × 3000 / 2000 × 1500

- Megapixels: 2.3 MP

- Repeat accuracy (Z σ): 0.05 mm @ 1.0 m

- VDI/VDE accuracy: 0.1 mm @ 1.0 m

- Exposure time: 0.3 – 0.6 s

- Baseline: 180 mm

- Dimensions: 265 × 57 × 100 mm

- Weight: 1.6 kg

PRO S-GL

DEEP-GL

- Working distance: 1200–3500 mm

- Near FOV: 1200 × 1000 mm @ 1.2 m

- Far FOV: 3500 × 2800 mm @ 3.5 m

- Resolution: Depth map 2048 × 1536

- RGB: 2000 × 1500

- Megapixels: –

- Repeatability (Z σ): 1.0 mm @ 3.0 m

- VDI/VDE accuracy: 3.0 mm @ 3.0 m

- Capture time: 0.5 – 0.9 s

- Baseline: 300 mm

- Dimensions: 366 × 77 × 92 mm

- Weight: 2.4 kg

DEEP-GL

NANO ULTRA-GL

- Working distance: 250–800 mm

- Near FOV: 220 × 165 mm @ 0.25 m

- Far FOV: 770 × 550 mm @ 0.8 m

- Resolution: 2400 × 1800

- Megapixels: 4.3 MP

- Repeatability (Z σ): 0.1 mm @ 0.6 m

- VDI/VDE accuracy: 0.1 mm @ 0.6 m

- Exposure time: 0.5 – 0.9 s

- Baseline: 86 mm

- Dimensions: 125 × 46 × 76 mm

- Weight: 0.7 kg

NANO ULTRA-GL

NANO-GL

- Working distance: 300–600 mm

- Near FOV: 220 × 150 mm @ 0.3 m

- Far FOV: 440 × 300 mm @ 0.6 m

- Resolution: 1280 × 1024

- Megapixels: 1.3 MP

- Repeatability (Z σ): 0.1 mm @ 0.5 m

- VDI/VDE accuracy: 0.1 mm @ 0.5 m

- Exposure time: 0.6 – 1.1 s

- Baseline: 68 mm

- Dimensions: 145 × 51 × 85 mm

- Weight: 0.7 kg

NANO-GL

UHP-140 -GL

- Working distance: 300 ± 20 mm

- Near FOV: 135 × 90 mm @ 0.28 m

- Far FOV: 150 × 100 mm @ 0.32 m

- Resolution: Depth map 2048 × 1536

- Megapixels: 3.0 MP

- Repeatability accuracy (Z σ): 2.6 μm @ 0.3 m

- VDI/VDE accuracy: 0.03 mm @ 0.3 m

- Exposure time: 0.6 – 0.9 s

- Baseline: 80 mm

- Dimensions: 260 × 65 × 142 mm

- Weight: 1.9 kg