Conveyor & transfer line systems

MONTECH has grown from the Swiss machine builder to the well-known components supplier for mounting technology (MONtage-TECHnologie)

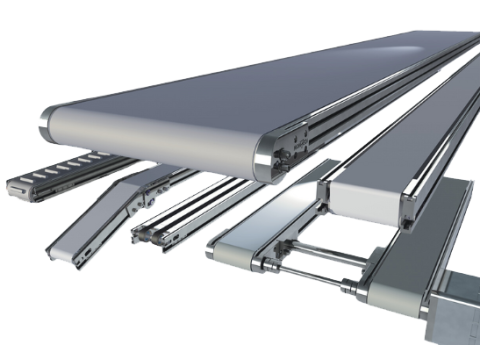

MONTECH supplies a wide range of small to large conveyor systems:

- KTB: width 45mm to 250mm

- TB/TBD: width 60mm to 250mm

- GTB: width 200mm to 800mm

MONTECH also supplies 2 types of transfer systems on which workpiece carriers run.

- LT40

- LTE

GTB Max

Max conveyors GTB are used to carry parts to or from the various manufacturing stations, or combined to form complete transport systems. The modular construction of the system permits simple adaptation to specific customer requirements.

- The following chassis widths are available: 200, 300, 400, 500, 600, 700 and 800 mm.

- The possible belt length is between 1 and 6 m.

- The conveyor is driven by a 230/400 V spur gear motor.

- This permits transportation of up to 125 kg in conveying mode.

- The end drive version can be fitted above or below the belt depending on available space.

- The top drive version can transport products up to 80 mm high.

GTB Max

KTB Minidrive

Minidrive conveyors KTB are used to carry parts to or from the various manufacturing stations, or combined to form complete production lines. Thanks to the compact design and integrated control, the minidrive conveyor is the ideal solution for many applications.

- The belt is driven by a regulated, brushless 24 V DC motor with variable speed and selectable direction.

- The following chassis widths are available: 45, 60, 80, 105, 140 185 and 250 mm.

- Available in single belt or dual belt version.

- In spite of a compact drive unit, up to 20 kg can be transported.

Note: The KTB minidrive conveyor belt is a phasing-out model. The successor model is the TB30 conveyor belt.

KTB Minidrive

TB30 / TB40

The TB conveyor belt offers several configuration options:

- single belt conveyor

- dual belt conveyor

- tandem conveyor

The TB conveyor also forms the basis of Montech's handling systems. Modular components simplify adjustment and ensure that accessories can be fitted easily and quickly to the chassis.

With a maximum length of 10 m, chassis widths from 45 to 250 mm are available. Speeds up to 80 m/min (DC motor with controller) and 30 m/min (AC motor) can be achieved.

TB30 / TB40

The TB30 conveyor is used to carry parts to or from the various manufacturing stations, or can be combined to form complete production lines. The conveyors modular design allows them to be easily and inexpensively extended or shortened at any time, making them ideal for customer specific transport solutions.

- The drive unit with centre drive can be placed free on length of the chassis. The change from end drive to centre drive and vice versa is possible without a belt exchange.

- The motor of the conveyor has an efficiency-optimized drive and is therefore very energy-efficient.

- In addition, the TB30 is more user-friendly and less expensive than its previous models (KTB/TB).

- With a maximum length of 10 m chassis widths from 45 to 250 mm are available.

The TB40 conveyor is driven by a 24 V brushless DC drum motor with built-in control unit with 4 digital inputs (pre-programmed speeds) and 1 analogue input (variable speed). With the drive integrated into the drive roller, the conveyor belt is very compact in design.

- It can carry up to 80 kg in transport mode.

- Chassis widths are available from 300 up to 800 mm.

- The possible band length is between 1 and 6 m.

- The diameter of the deflection rollers 60 mm (drive roller 73 mm) allows the use of cleated belts.

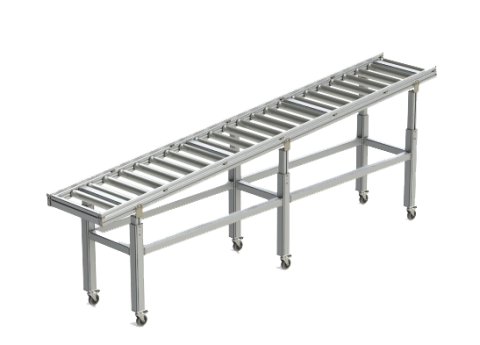

RB40

The RB40 gravity roller conveyor transports containers, boxes, skids and other loads with flat, rigid bottom surfaces.

Load capacity goes up to 150 kg/m.

The roller conveyor is an addition to the TB40 conveyor and is therefore geometrically and optically matched to it.

The desired angle of inclination can be quickly set with the adjustable feet.

RB40

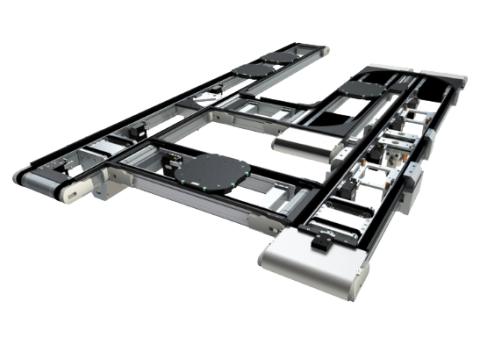

LT40

The LT40 transfer system is a dual toothed belt system on which individual transfer plates or product carrier run at a speed of up to 65.61 fpm.

The LT40 is available in three sizes, so there is an optimal configuration for every application. The transfer plates or product carrier come in six different sizes and can accommodate loads up to 37 lb. They can be equipped with RFID so that they can be identified at any time. The conveyors are designed to customer specifications, and two types of drive controllers are available to regulate speed.

LT40

- Size workpiece carrier: 200 x 200 mm & 320 x 480 mm

- Drive unit: directly integrated into the shaft

- Max. pressure position unit: 16,8 kg

- Speed: 20 m/min

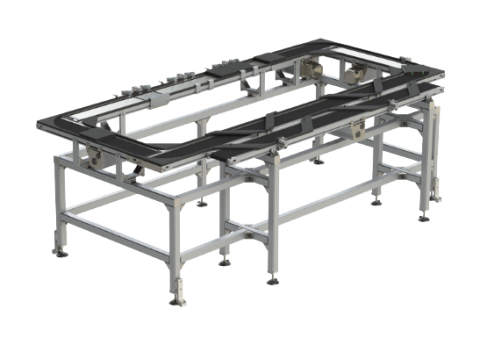

LTE

The LTE system is a single-belt, asynchronous transfer system that automatically transports workpiece holders or carriers to workstations according to their assembly sequence.

The parts or assemblies requiring sequential processing are attached to standardized workpiece holders made of high-strength PET plastic, and are transported on single-belt conveyors.

The modular design allows the modification, or future expansion of the system to be completed easily and with minimal expense.

LTE

- Size Workpiece holders: 80 x 80 mm & 225 x 225 mm

- Drive mode: TB30 center drive

- Max. pressure position unit: 5kg

- Speed: 7,7 - 19 m/min