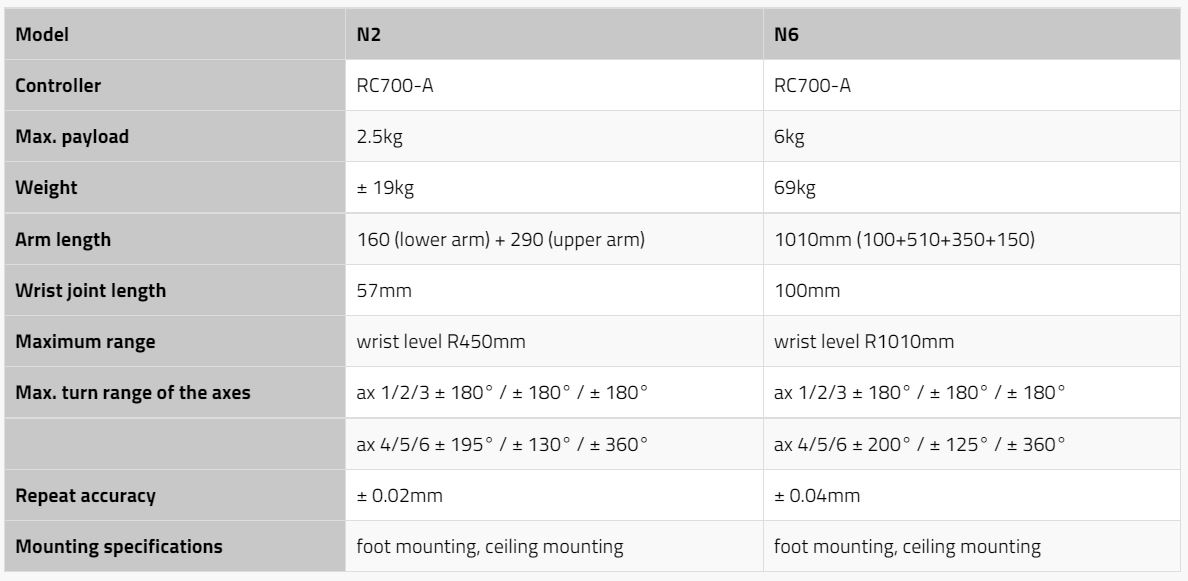

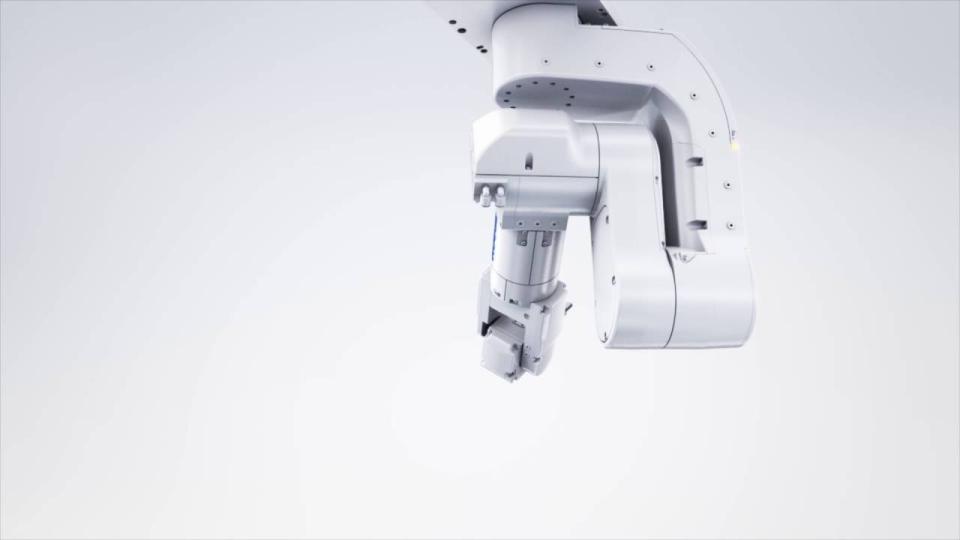

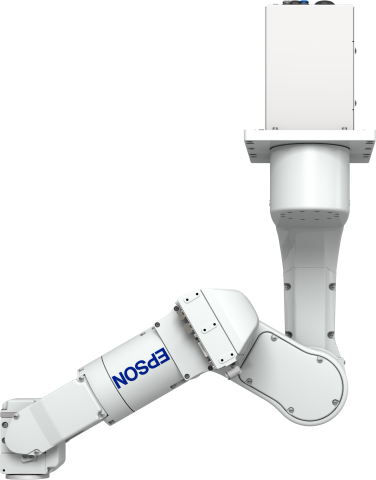

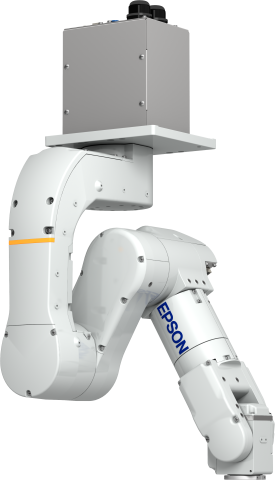

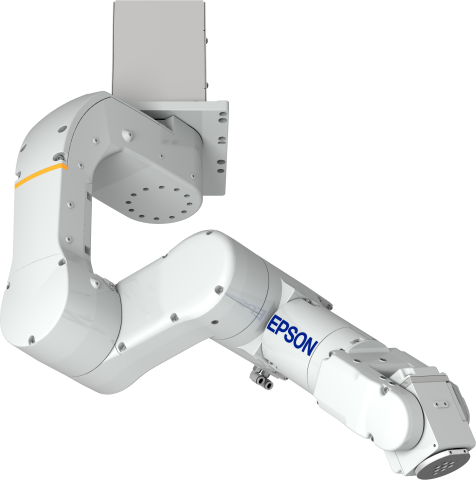

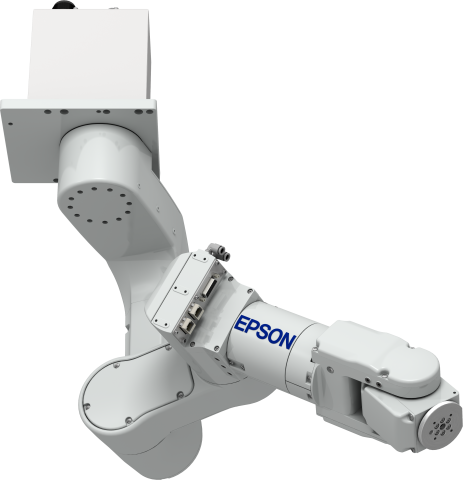

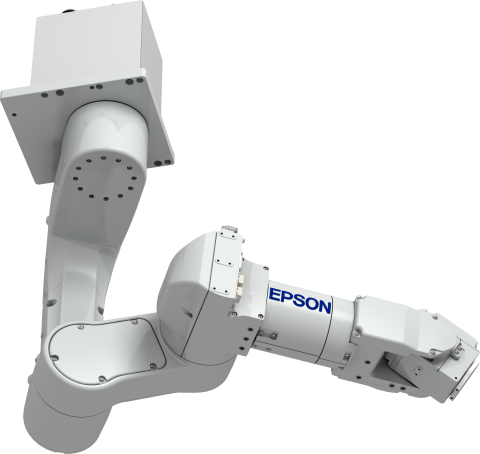

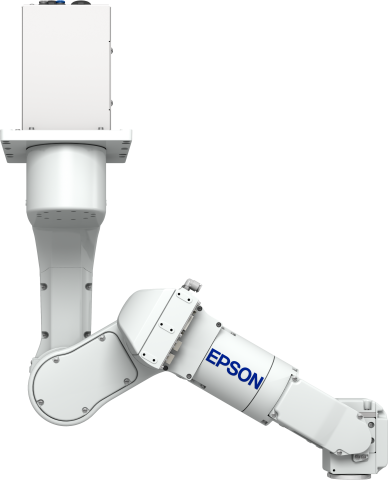

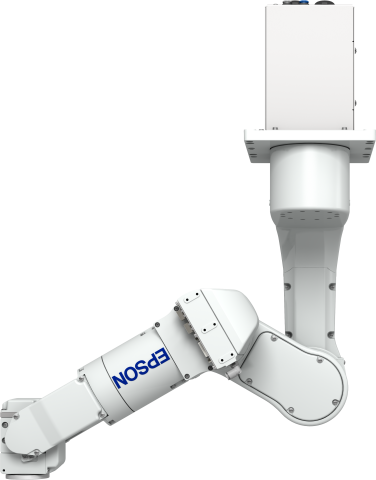

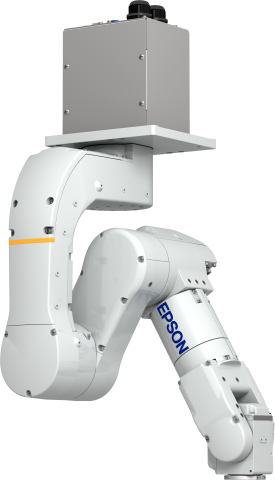

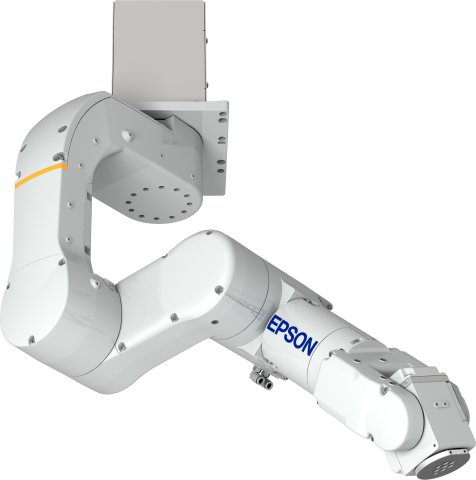

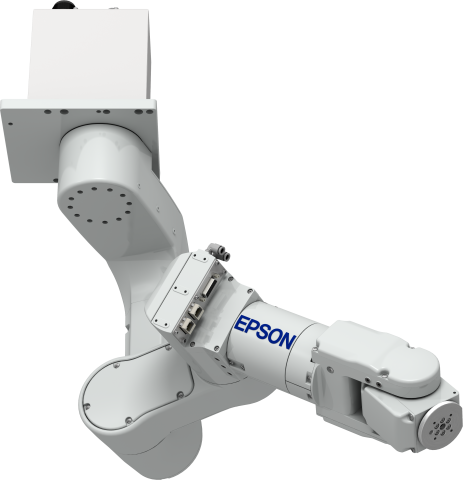

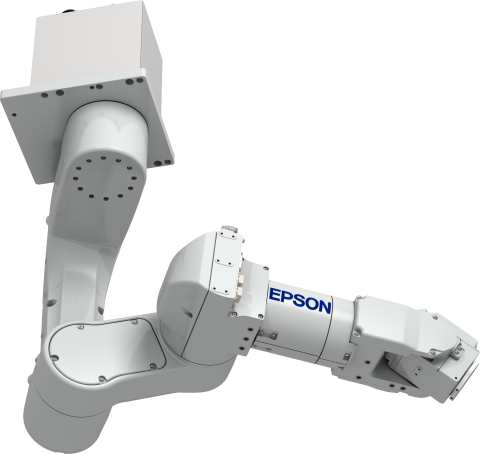

The robots in the new N-series have an innovative articulated arm, therefore they can be installed in very small areas. Floor-mounted, the N6 has a 6-kg payload capacity and an arm length of 1,000 mm, both considerably larger than the N2. The N6 is ideal for tasks such as loading and unloading electronic components and automotive parts to and from test equipment or shelving and removing medical products. It can reach a wide range of places such as high and low shelves using a smaller installation footprint than earlier 6-axis robots. These features will enable the robot to increase productivity and the efficiency with which factory space is used. In other words, this robot has a smaller installation footprint than classical 6-axis robots.

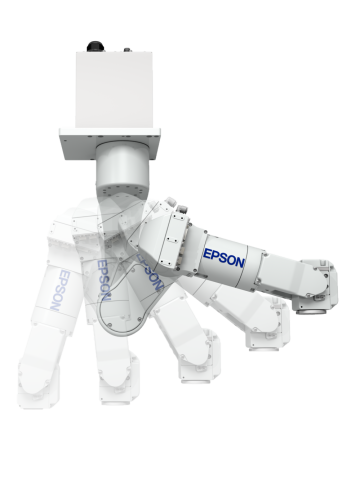

The structure of the new arm maximizes the space efficiency of the N-series. Hence these robots can be mounted in a space as small as 600 square mm, the equivalent of the space occupied by a human worker. These robots reduce cycle times and offer a higher productivity because the arm will collide nor with the base nor with other objects when it is folded. So, less movements are needed to avoid collisions with objects in the environment.

The characteristics of the N series robots make them ideal for assembly, inspection of electronic products, automotive, medical, …. They can be used to automate countless tasks, such as screwing, assembling, manipulating various materials, loading of products in test systems, …